Overview: Let heat source pass through the sealed Jacket The heat will be transmitted to raw material to be dried through inner shell,Under driving of power,the tank is rotated slowly and the raw material.

DESCRIPTION

SZG Series Double cone Rotating Vacuum Dryer is a new generation drying device developed by our factory on the basis of combining the technology of similar equipment. It has two connecting ways, belt connection and chain connection. Therefore, the dryer is stable in operation. The special design guarantees two shafts realize good concentricity. The heat medium and vacuum system all adapt reliable rotating connector with the technology from USA. On this basis, we also developed SZG-A. It can carry out steeples speed change and constant temperature control. As a specialized factory in drying industry, we supply hundred sets to the customers every year. As for working medium, it may be thermal oil or steam or hot water. For drying the adhesive raw material, we have designed specially a stirring plate buffer for you.

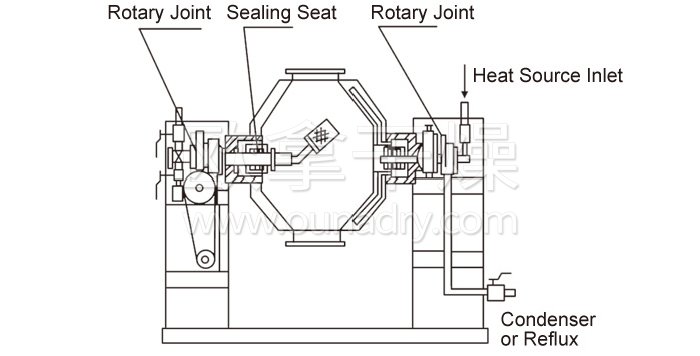

WORKING PRINCIPLE

1) When the heat source (hot water, low pressure steam, or thermal oil) pass through the sealed jacket, the heat will be transmitted to raw material through the inner shell;

2) Under action of driving power, the tank is rotated slowly and the raw material is mixed continuously. The purpose of reinforced drying can be realized;

3) The raw material is under vacuum condition. When steam pressure is dropping, it makes the moisture (solvent) at the surface of raw material become saturation and then evaporates. The solvent will be discharged through vacuum pump.

4) The moisture (solvent) of raw material will infiltrate, evaporate and discharge continuously.

5) The production processes are carried out continuously and the drying can be done in a short time.

APPLICATION

This dryer is suitable for the raw materials that need to concentrate, mixed and dried at low temperature (for example, biochemistry) products in chemical, pharmaceutical and foodstuff industries. Particularly it is suitable for the raw materials that are easy to be oxidized, volatilized and have heat sensitivity and is toxic and not permitted to destroy its crystal in drying process.

FEATURES

1) Use automatic constant temperature control if the heat source is thermal oil. It can be used for drying biology products and mineral raw materials. The temperature of operation can be adjusted form 20 ~ 160°C.

2) The heat efficiency will be 2 times or higher comparing to the common dryer.

3) The heating method is indirect drying so the raw material will not be polluted. It is in conformity with the requirement of GMP. 4) The dryer is easy for cleaning and maintenance.

TECHNICAL PARAMETERS

| Item \ Model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

|

volume inside the tank (L) |

100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

|

Volume to fill raw material (L) |

≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

|

Heating area (m2) |

1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

|

revolution ( rpm) |

4 - 6 | |||||||||

|

power of motor (kw) |

0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

|

occupiedarea, L×W (mm) |

2160 ×800 |

2260 ×800 |

2350 ×800 |

2560 ×1000 |

2860 ×1300 |

3060 ×1300 |

3260 ×1400 |

3760 ×1800 |

3960 ×2000 |

4400 ×2500 |

|

rotating height (mm) |

1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

|

design pressure |

-0.1-0.15 | |||||||||

|

design pressure of jacket (MPa) |

≤0.3 | |||||||||

|

working temp- erature(°C) |

In the tank≤85 jacket≤140 | |||||||||

|

When use con- densator, |

2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

|

model and power of vacuum pump |

2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

|

When don,t use condensator, |

SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

|

model and power of vacuum pump |

1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

SelectionBelt dryers have a wide range of applications, and currently have their abilities in the pharmaceutical, food, biological, chemical …

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…