Overview: Tt is well known that vacuum drying is to put raw material under the state of vacuum fo r heating and drying If use vacuum to pump air and humidity out,the dry speed will be faster.

FEATURES

1) The boiling point of raw material will be decreased under the vacuum condition and make the evaporator increases the pushing force of heat transfer.

2) The heat source can be low pressure steam or waste heat;

3) The loss of the heat during the evaporation is only a little.

4) The disinfection treatment can be carried out before drying and there is no impurity material mixing during drying process. It is in conformity with the requirement of GMP;

5) Static vacuum dryer will not damage the shape of raw materials.

WORKING PRINCIPLE

Vacuum Drying is to let the raw material to be dried at vacuum condition. It uses vacuum pump to pump damp air out and make the working chamber form vacuum status. Therefore, the drying speed of raw material is improved and the energy is saved greatly. Notes: The solvent of raw material can be collected by using a condenser. If the solvent is water, the condenser is not required in order to save investment cost.

APPLICATION

This dryer is suitable for drying heat sensitive raw materials that can decompose or polymerize or deteriorate at high temperature. It is widely used in pharmaceutical, chemical, foodstuff and electronic industries.

Technical parameters

| Item / Specification | YZG-600 | YZG-800 | YZG-1000 | YZG-1400A |

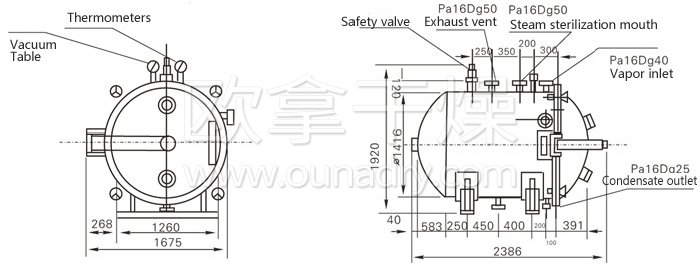

| Inner Dimension of the Dryer (mm) | Φ600×976 | Φ800×1247 | Φ1000×1527 | Φ1400×2054 |

| Outer Dimension of the Dryer (mm) |

1135×810 ×1024 |

1700×1045 ×1335 |

1693×1190 ×150 |

2386×1675 ×1920 |

| Qty of Layers | 4 | 4 | 6 | 8 |

| Distance of Layers | 82 | 82 | 102 | 102 |

| Dimension of Tray (mm) |

310×600 ×45 |

520×410 ×45 |

520×410 ×45 |

460×640 ×45 |

| Qty of Trays | 4 | 8 | 12 | 32 |

| Inside Pressure of Drying Rack (MPa) | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 |

| Working Temperature of Drying Rack (°C) | 35-150 | 35-150 | 35-150 | 35-150 |

| Vacuum Degree of Empty Dryer | -0.09~0.096 | |||

|

Water Evaporation Rate (In the condition of -0.1MPa with temperature of 110°C) (kg/m2•hr) |

7.2 | 7.2 | 7.2 | 7.2 |

|

Vacuum Pump (for the dryers with condenser) |

2X-15A 2KW |

2X-30A 3KW |

2X-30A 3KW |

2X-70A 5.5KW |

|

Vacuum Pump (for the dryers without condenser) |

SK-0.8 2.2KW |

SK-2.7 4KW |

SK-3 5.5KW |

SK-6 11KW |

| Weight (kg) | 250 | 600 | 800 | 1400 |

Note:SZ water ring vacuum pump can be used together with mechanical pressure increasing pump in order to increase vacuum.

Ordering Information

1) Please choose the suitable model according to the primary moisture content, final moisture content, temperature, vacuum degree, and drying time. The heat source can use steam, hot water, thermal oil, and electricity. If the customer required increasing the drying capacity by add more trays, please specify in the order. 2) If the customer required installation or spare parts, please specify in the order.

3) Customized design service available.

4) We guarantee the quality of the dryer and we ensured the spare parts for the dryer is available in a long term.

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

SelectionBelt dryers have a wide range of applications, and currently have their abilities in the pharmaceutical, food, biological, chemical …

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…