Application client

Qinghai Lithium Industry Co., Ltd.

Choose products

PLG series disc continuous dryer

project description

The special disc continuous dryer for lithium carbonate has strong pertinence, practicability and high energy efficiency. When we produce equipment for users, we design and manufacture the most suitable and best quality drying equipment for users according to the characteristics of the required drying products, the user's process requirements, and the experience accumulated over the past few decades.

Features

(1) Easy to adjust and control, strong applicability

1. The drying process can be optimized by adjusting the thickness of the material layer, the spindle speed, the number of harrow arms, the type and size of the harrow blades.

2. Each layer of drying tray can be filled with heating or cooling media to heat or cool the materials. The materials are heated evenly, and the temperature control is accurate and easy.

3. The residence time of the material can be precisely adjusted.

4. Single material flow direction, no back-mixing phenomenon, uniform drying, stable quality, no need for remixing.

(2) The operation is simple and easy

1. The operation of driving and stopping the dryer is very simple.

2. After stopping the feeding, the rake leaves that convey the material can quickly empty the material in the dryer.

3. Through the special large-size inspection door mirror, the inside of the equipment can be carefully cleaned and observed.

(3) Low energy consumption

1. The material layer is very thin, the spindle speed is low, and the material conveying system requires low power and low power consumption.

2. Drying by conduction heat has high thermal efficiency and low energy consumption.

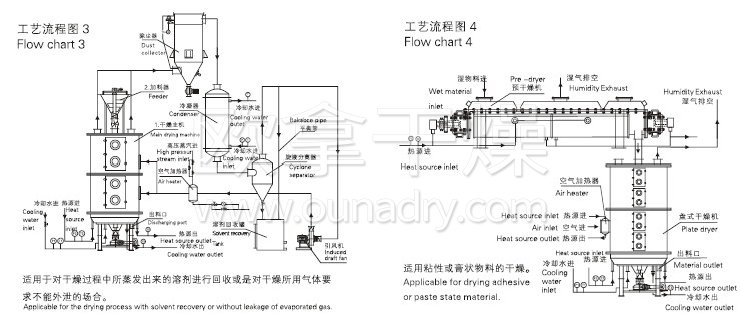

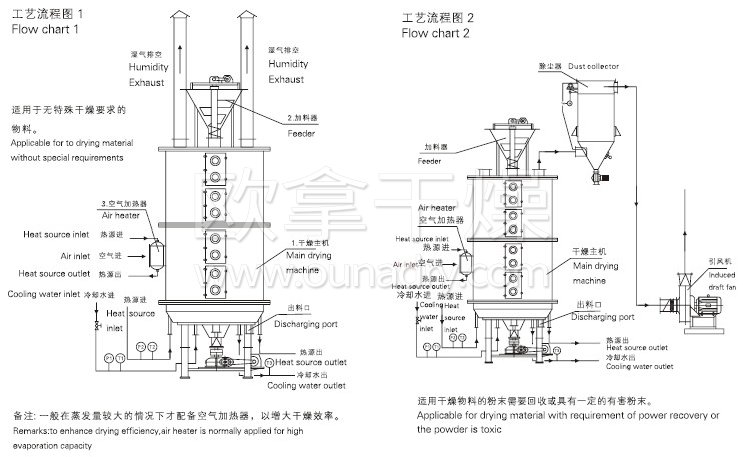

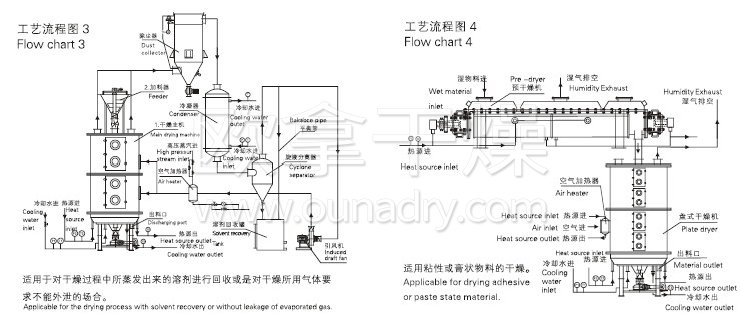

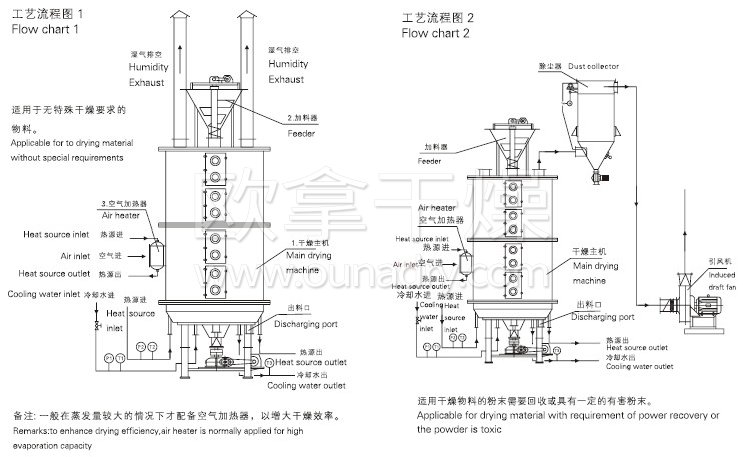

(4) The operating environment is good, the solvent can be recycled, and the dust emission meets the requirements

1. Atmospheric pressure type: Due to the low air velocity in the equipment and the low humidity distribution in the equipment, it is difficult for dust to float to the top of the equipment, so the exhaust from the top moisture exhaust port contains almost no dust.

2. Airtight type: Equipped with a solvent recovery device, which can easily recover organic solvents in wet gas. The solvent recovery device is simple and the recovery rate is high. For flammable, explosive, toxic and easily oxidized materials, nitrogen can be used as a moisture-carrying gas for closed-circuit circulation to make it safe to operate. It is especially suitable for drying flammable, explosive and toxic materials.

3. Vacuum type: A disc dryer operated under vacuum, especially suitable for drying heat-sensitive materials.

(5) Easy to install and small area

1. The dryer leaves the factory as a whole and is transported as a whole. It only needs to be hoisted in place, and the installation and positioning are very easy.

2. Due to the layered arrangement and vertical installation of the drying plate, even if the drying area is large, the floor space is small.

Overview

Disc continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine that it has high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. Features. It is widely used for drying operations in the chemical, pharmaceutical, pesticide, food, feed, agricultural and sideline product processing industries. It is well received in practice in various industries. It can be divided into three types: normal pressure, airtight and vacuum; 1 2 0 01, 5 0 02, 2 0 03, 0 0 and other specifications; A (carbon steel), B (stainless steel in contact with the material), C in On the basis of B, the steam pipeline, the main shaft and the bracket are made of stainless steel, the cylinder and the top cover are lined with stainless steel) three or two kinds of materials, a drying area of 4 to 180 m, a total of hundreds of models of series products, and can Provide matching auxiliary equipment to meet the needs of users for drying various materials.

application

The drying equipment is mainly used for drying and cooling powder and granular materials in industries such as medical intermediates, pesticides, chemicals, medicine, food, and feed.

(1) Organic chemicals: polyvinyl chloride resin, polytetrafluoroethylene resin, fumaric acid, anthraquinone, nitroanthraquinone, p-aminophenol, melamine, cyanuric acid, p-aminobenzoic acid, antioxidant 1 6 8 , Chromol AS, stearate, aniline, nitroaniline, dipentaerythritol, paraffin chloride, calcium formate, triethylene diamine, sodium benzene sulfinate, isophthalic acid, sodium dimethyl pentasulfonate, Organic chemical raw materials and intermediates such as thiourea, oil-soluble nigrosine dyes, acid black dyes, etc.

(2) Inorganic chemical industry: light calcium carbonate, activated calcium carbonate, nanometer superfine calcium carbonate, magnesium carbonate, aluminum hydroxide, white carbon black, strontium carbonate, barium carbonate, formazan, lithopone, sodium sulfate, potassium sulfate, Microsphere catalyst, magnesium hydroxide, copper sulfate, nickel sulfate, ammonium nickelate, sodium molybdate, sodium chloride, potassium chloride, calcium chloride, sodium fluoride, cryolite, iron oxide red, lithium hydroxide, hydrogen Nickel oxide, zirconium hydroxide, calcium carbonate, sulfur, etc.

(3) Medicine and food: Ampicillin, Deng's salt, L-phenylglycine and intermediates, cefotaxime, ceftriaxone, methamphetamine, cimetidine, vitamin b, vitamin c, medicinal magnesium metasilicate, caffeine , Tea, flower extracts, ginkgo biloba, chocolate powder, starch, corn germ buds and other raw materials and medical intermediates.

(4)Feed, fertilizer: potassium carbonate, biological potash fertilizer, protein feed, chlortetracycline for feed, bran, distiller's grain, grain, herbicide, cellulose, feed calcium hydrogen phosphate, etc.